- +(94) 71 196 7228

- info@seclk.com

- Mon - Fri 8:00 - 17:30

- August 26, 2023

- by SE Consultants

Stud Length Requirements of Timber stud walls

Introduction

I usually use 92-5/8″ studs when I am building standard 8′ tall walls – they sit in piles at my nearby lumber yards next to piles of 8′ long studs. I recently saw (example) that there are three pre-cut sizes available:

· 92-5/8″ : used for 8′ ceiling heights

· 104-5/8″ : used for 9′ ceiling heights

· 116-5/8″: used for 10′ ceiling heights

Figure 1– Typical Wall section- Source- https://en.wikipedia.org/wiki/Wall_stud

In this post, I thought I would take a look at these pre-cut sizes to (1) learn why these values are used, and (2) to decide if any of them would be appropriate for my building activities. I recently saw one well-known carpenter make a plea for a 94-1/8″ long studs. I will also examine this length to see why it may make sense in some circumstances.

Background

Definitions

Stud

Stud is shortening of the term “wall stud”, which is a vertical framing member in a building’s wall of smaller cross section than a post. They are a fundamental element in building framing

In North America, studs are usually specified by their nominal width and thickness (e.g. 2″x4″, 2″x6″). The actual dimensions differ from the nominal dimensions (e.g. 1.5″x3.5″,1.5″x5.5″). It is a weird way of specifying dimensions, but that is what we do.

Plate

Plate is a shortening of the term “wall plate”. A wall plate is a horizontal, structural, load-bearing member in wooden building framing.

Pre-Cut Length

Historically, wall studs were available standard lengths given in an integral number of feet (e.g. 8′, 9′, 10′). Similarly, home ceiling heights are often given in even number of feet (e.g. 8′, 9′, 10′). Because the ceiling height is determined by the combined height of studs and plates, achieving a specific ceiling height (e.g. 8′) means cutting every standard length stud on site. Rather than cut each stud on site, it is more efficient to simple purchase the studs pre-cut (i.e. cut at the factory) to the proper length for a ceiling height that is an integral number of feet.

Subfloor

A rough floor laid on floor joists and serving as a base for the finish floor. It is usually made of plywood and/or particle board.

Strapping

In construction, strapping consists of thin strips of wood or other material used to level or raise surfaces of another material such as to prevent dampness, to make space for insulation, or to level and resurface ceilings or wall.

green building

Green building refers to both a structure and the using of processes that are environmentally responsible and resource-efficient throughout a building’s life-cycle: from siting to design, construction, operation, maintenance, renovation, and demolition.

Optional Strapping Use

My current house has wallboard that is secured directly to the ceiling joists. When the ceiling is lit from the side, it is obvious that the wallboard is not flat because I can see light and dark area on the ceiling – shadows caused by the sagging of the wallboard between the studs. I do not like that look, which makes me very interested in doing everything I can to ensure that my ceiling is flat.

One common way to ensure that your ceiling is flat is to attach 1″x3″ (actual dimensions: 0.75″x2.5″) strapping to the ceiling joists. This approach allows you to reduce the distance between fasteners on the ceiling and make the sagging imperceptibly small. Figure 2 shows an example of ceiling joists covered with strapping.

Figure 2– Strapping Used to Provide Support for Ceiling Wallboard and a Wiring Channel.

Ceiling Height Options

While the most common ceiling height in North America is nominally 8′, you will occasionally see ceiling heights of 9′ and 10′. Because there are three commonly used ceiling heights, I see three pre-cut lengths.

Fun Wallboard Facts

§ In my region, ceiling wallboard needs to be 5/8″ thick because it has a fire rating.

§ Wall board is available in widths of 48″ and 54″.

48″ and 54″ wallboard works perfectly for 8′ tall and 9′ tall ceilings, respectively. I have not seen a consensus on the best way to place wallboard on a 10′ ceiling. Most of the pros I have seen use horizontally placed standard width wallboard panels plus a partial piece placed near the floor.

§ Small gaps along the floor are easily hidden with molding and make installation easier.

Standard practice allows a 1/4″ to 1/2″ gap between the bottom wallboard edge and the floor. This gap allows you to place wallboard without any need to force a piece into place.

8′ Ceilings

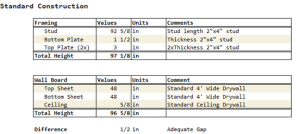

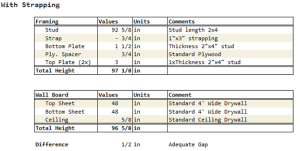

The most common ceiling height in North America is 8′, and Figure 3 shows how a wall for this ceiling height would be framed. The actual height of an 8′ ceiling is 8′ 1/2″ = 97.125″-0.625″, measured from the subfloor. Since the finished floor height is ~0.5″ thick, the final height is ~8′.

Figure 3– 8′ Wall/Wallboard Height (No Strapping).

Figure 4– 8′ Wall/Wallboard Height (With Strapping).

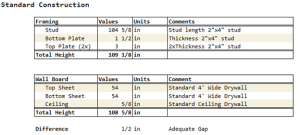

9′ Ceilings

Another common ceiling height in North America is 9′, and Figure 4 shows how a wall for this ceiling height would be framed. The actual height of a 9′ ceiling is 9′ 1/2″ = 109.125″-0.625″, measured from the subfloor. Since the finished floor height is ~0.5″ thick, the final height is ~9′.

Figure 5– 9′ Wall/Wallboard Height (No Strapping).

Figure 6– 9′ Wall/Wallboard Height (With Strapping).

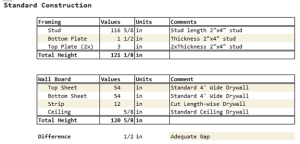

10′ Ceilings

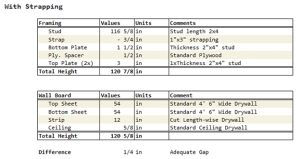

Occasionally, you see a ceiling height in North America of 10′, and Figure 4 shows how a wall for this ceiling height would be framed. The actual height of an 10′ ceiling is 10′ 1/2″ = 121.125″-0.625″, measured from the subfloor. Since the finished floor height is ~0.5″ thick, the final height is ~10′.

Figure 7– 10′ Wall/Wallboard Height (No Strapping).

Figure 8– 10′ Wall/Wallboard Height (With Strapping).